Customer:

General Motors

Request:

New proton conducting membranes for hydrogen-fuel cell powered vehicles with an improved performance profile, especially in climatically demanding regions, are to be developed.

Solution: New polymers

Development of new hydrocarbon membranes that work without fluorine-containing components and show a significantly improved conductivity with little swelling, and also significantly better mechanics.

Result:

Polymaterials membrane with clearly superior performance values compared to membranes containing fluorine.

Customer:

European specialty chemicals company

Request:

Biopolymer (polylactide – PLA) with significantly improved mechanical properties (toughness) and hydrolysis resistance with highly cost efficient production process at the same time.

Solution: New polymers and new compounds

In an integrated project between our synthesis lab and pilot plant, a reactive extrusion process of lactide and co-monomers in a planetary roller extruder was established. In addition, comprehensive database of blends and compounds to cover a wide range of properties was set up.

Result:

Customer:

Chemical company

Request:

Development of an optimized recycling material as a replacement for virgin plastic without compromising product performance.

Solution: New compounds

Screening of additives and blend partners for the plastic recyclate with our patented X-Plorator® technology. Prediction of an optimal recipe based on the model generated. Production of samples of the predicted compounds with the highest market potential within two weeks of project start.

Result:

Market launch of two new products in a very short time frame that the customer did not consider possible.

Customer:

Silicon Valley AI start up

Request:

New high-performance biopolymers for high-value applications based on AI / biotech developments.

Solution:

Development of a synthesis process for scale-up and transfer to the pilot plant scale for upscaling the first product quantities (target scale: 10 t).

Result:

Successful test applications of bio-based new polymers within the target industry.

Customer:

General Motors

Request:

Fluorine free proton conducting membranes with performance and durability comparable to PFSA-membranes.

Solution:

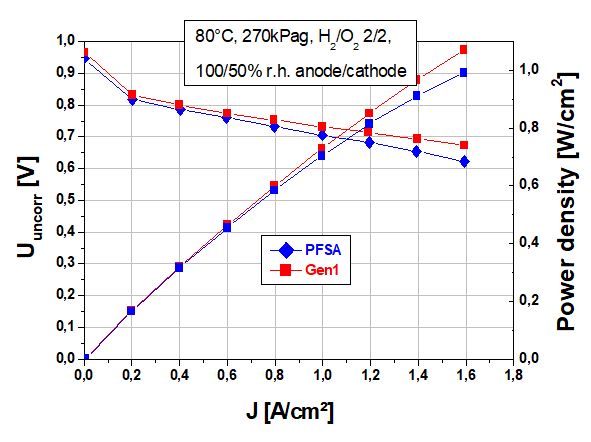

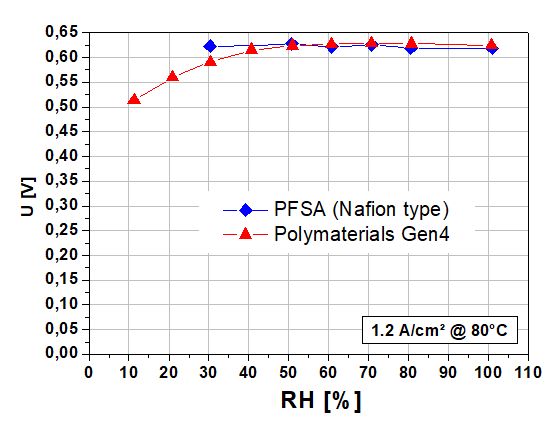

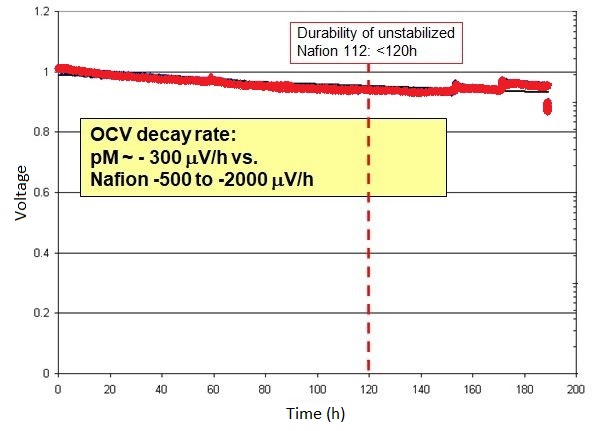

Polymer electrolyte membranes from polyperfluoro sulfonic acids (PFSA) such as Nafion, Flemion, Aciplex etc. are the typical choice for proton conducting membranes in PEM fuelc cells and electrolysers.

Fluorine free polymers based on polyarylene ethers like the SPATS-Triblock copolymers developed by Polymaterials can indeed achieve comparable performance and durability for the application in PEM fuel cells.

Result:

Comparable performance like PFSA-membranes, even under reduced humidity, partly higher durability then Nafion.

Comparison PFSA-membrane (Nafion-type) with Polymaterials Triblock membrane;

◆ Nafion, ■ Polymaterials Gen1, ▲ Polymaterials Gen4

(all tests performed with non-optimized MEAs (CCDM))